Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowWhy Use Enameled Aluminum Magnet Wire in Electrical Applications?

In today's rapidly evolving electrical industry, the choice of materials is crucial for efficiency and reliability. Enameled Aluminum Magnet Wire stands out among options. Industry expert John Smith emphasizes, "Using Enameled Aluminum Magnet Wire can improve performance while reducing costs.” This quote illustrates the significant advantages of this wire in electrical applications.

Enameled Aluminum Magnet Wire is lightweight and offers excellent conductivity. Its thermal properties also enhance performance in high-temperature environments. Many manufacturers have adopted this wire for motors and transformers, recognizing its benefits. However, challenges remain. Not all applications may appreciate its unique traits.

The market is still exploring some aspects of Enameled Aluminum Magnet Wire. Some users face difficulties in handling the material properly. It is essential to understand the wire's specific requirements for optimal performance. Addressing these challenges is vital for the sector's advancement.

Benefits of Enameled Aluminum Magnet Wire in Electrical Applications

Enameled aluminum magnet wire offers significant advantages in electrical applications. Its lightweight nature reduces overall weight in designs. For instance, aluminum has only one-third the weight of copper. This feature can enhance efficiency, especially in mobile devices and electric vehicles. Furthermore, industry reports indicate that aluminum wire can conduct electricity at approximately 61% the efficiency of copper. This means that, despite a lower conductivity rate, aluminum's advantages can offset some performance losses.

Another benefit is cost-effectiveness. According to recent data, aluminum wire can be 30% cheaper than copper. This makes it an attractive option for manufacturers aiming to reduce production costs. However, aluminum requires careful handling due to its susceptibility to corrosion. Some studies highlight that without proper insulation, aluminum can degrade faster than copper. It’s crucial for engineers to consider protective coatings.

Additionally, enameled aluminum wire is easier to wind, which can simplify the manufacturing process. This advantage can lead to faster production times and reduced labor costs. Still, challenges remain. Sufficient training in handling this material is necessary. Missteps in installation may lead to insulation failures or performance issues. Thus, using enameled aluminum wire requires a balance of knowledge and technique.

Comparative Properties of Enameled Aluminum and Copper Magnet Wires

Enameled aluminum magnet wire is gaining attention for its unique properties in electrical applications. When compared to copper magnet wire, it offers distinct advantages. Aluminum is lighter, which makes it easier to handle and install. This feature can be especially beneficial in applications where weight management is crucial. Additionally, the cost of aluminum is often lower, leading to potential savings in large-scale projects.

However, aluminum has some drawbacks. Its conductivity is lower than that of copper, which means engineers must use thicker wires to achieve similar performance. This can sometimes offset the initial cost savings. Furthermore, aluminum wire can be more prone to oxidation. The protective enamel layer is essential, as it helps prevent this issue. It’s important for manufacturers to ensure consistent enamel quality to maintain performance.

In real-world applications, these factors need careful consideration. Engineers often have to weigh the benefits against potential challenges. Misjudging the required wire size can lead to problems down the line. Proper testing and quality control are critical. The choice between enameled aluminum and copper wire should be based on a detailed analysis of project requirements and long-term performance.

Applications of Enameled Aluminum Magnet Wire in Various Industries

Enameled aluminum magnet wire plays a vital role in various industries. Its lightweight nature is a significant advantage for applications in electric motors and transformers. In automotive manufacturing, it is utilized in electric vehicle motors, contributing to energy efficiency. The wire's insulation helps in reducing energy loss, but ensuring the right level of insulation is crucial.

In the renewable energy sector, this type of wire is prominent in wind turbines and solar inverters. Its resistance to corrosion ensures long-lasting performance. However, the variability in quality can be a challenge. Engineers must test and examine the wire consistently.

The consumer electronics industry also benefits from enameled aluminum magnet wire. It's found in audio devices and compact appliances. Yet, manufacturers must pay close attention to wire thickness and insulation quality. Small mistakes can lead to significant performance issues. Balancing cost and quality is often a tricky aspect that requires ongoing evaluation and adjustment.

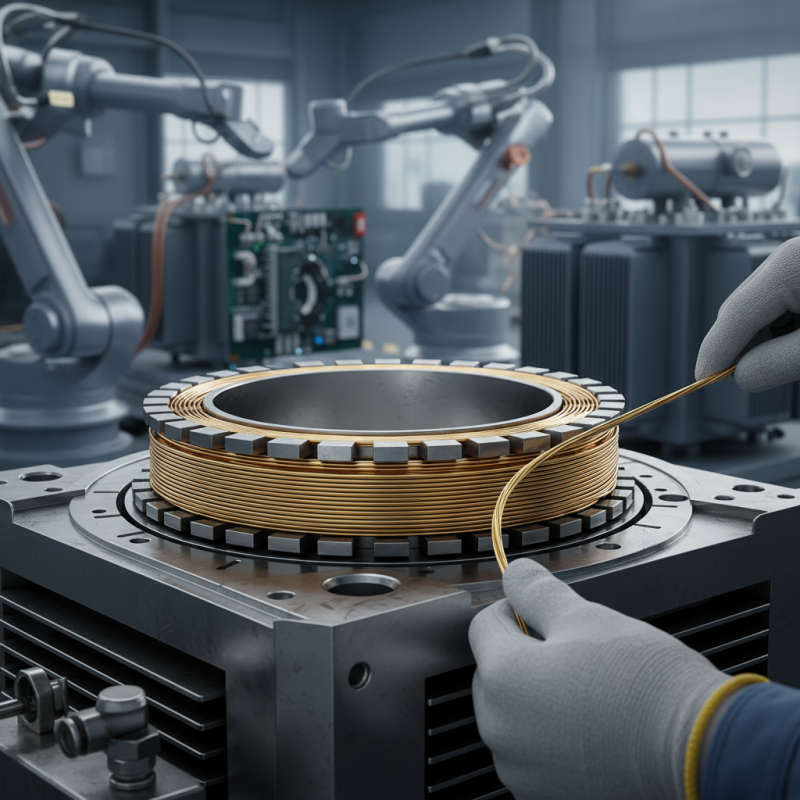

Manufacturing Process of Enameled Aluminum Magnet Wire

The manufacturing process of enameled aluminum magnet wire involves several intricate steps. Initially, aluminum wire is drawn to specific diameters. This is crucial. Precision impacts electrical performance and reliability. The drawn wire undergoes a cleaning process. This removes any contaminants, ensuring proper bonding with the enamel coating.

Next, the wire is coated with an insulating enamel. This layer protects it from potential damage during operation. According to industry reports, enamel coatings can withstand high temperatures, often exceeding 200°C. However, achieving uniform coating thickness is a challenge. Inconsistent application can lead to weak spots. These areas may compromise the wire's insulation over time.

After coating, the wire is cured. The curing process solidifies the enamel, enhancing its durability. This step is vital for ensuring long-term performance. Testing for continuity and insulation integrity follows. Despite advancements, human error can occur during testing. Improving quality control measures could be essential for better reliability. Ultimately, the manufacturing process must balance quality and efficiency while addressing potential pitfalls.

Performance and Durability Factors of Enameled Aluminum Wire

Enameled aluminum magnet wire is gaining traction in various electrical applications. Its performance characteristics are noteworthy. The insulation is robust, resisting high temperatures and ensuring long-lasting functionality. This durability is crucial for motors and transformers, where heat build-up can be problematic.

Moreover, aluminum is lighter than copper, making it an attractive option for certain industries. Despite this advantage, some users still question its performance in high-stress environments. They worry about its conductivity compared to copper. Yet, when properly engineered, enameled aluminum wire offers comparable efficiency.

Some challenges persist. Adhesion between the enamel and aluminum can be inconsistent. This inconsistency affects the reliability of the wire. Manufacturers must pay close attention to production techniques. Quality control becomes vital in ensuring that the wire meets specified standards. Testing and refining these processes could enhance overall performance.