Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register now5 Best Industrial Printer Machines for Efficient Production in 2023

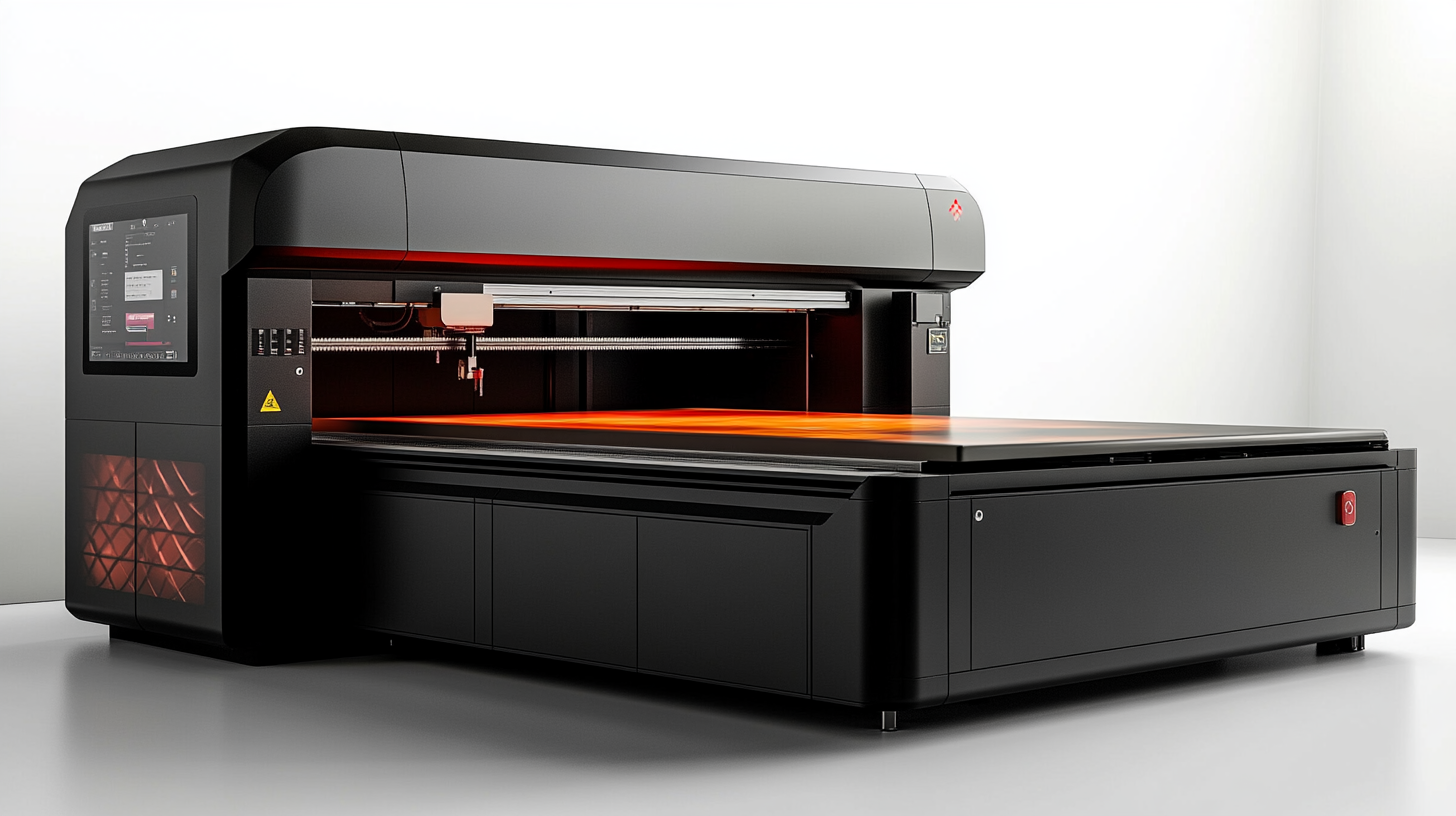

In the fast-paced world of manufacturing and production, having the right tools at your disposal can make all the difference. One critical piece of equipment that has evolved dramatically in recent years is the Industrial Printer Machine. These high-performance printers are not only designed to meet the demanding needs of industrial environments but also enhance efficiency and productivity. As businesses strive to optimize their operations, selecting the best industrial printer can significantly impact both the quality and speed of output.

As we dive into 2023, the variety of industrial printer machines available on the market is vast, each offering unique features and capabilities tailored to different production needs. Whether you require high-speed labels, durable packaging solutions, or intricate designs, choosing the right machine can streamline your workflow and reduce costs. In this blog, we will explore the five best industrial printer machines that stand out in terms of performance, reliability, and innovation, ensuring that your production line remains competitive and efficient.

Top Trends Shaping the Industrial Printing Industry in 2023

The industrial printing industry is undergoing significant transformation in 2023, driven by technological advancements and evolving market demands. The global printers market reached a valuation of USD 51.08 billion in 2023 and is projected to continue its upward trajectory, with an anticipated growth to USD 65.50 billion by 2030. This growth is largely attributed to the rising adoption of digital printing technologies, which offer enhanced efficiency and lower operational costs compared to traditional methods. 3D printing stands out as one of the most impactful trends in the industrial printing landscape. The global revenue for the 3D printers market was valued at USD 20.70 billion in 2023 and is expected to grow to USD 24.37 billion in 2024, marking a compound annual growth rate that signifies the technology's growing relevance. Industries, particularly healthcare, are leveraging this innovation to streamline production processes and develop customized solutions, as seen in the dental field where practitioners are increasingly investing in 3D printing capabilities. Furthermore, the digital printing sector is also expanding, with a market size estimated at USD 38.07 billion in 2023 and a projected growth rate of 6.2% through 2030. This shift toward digital methods is not only enhancing print quality but also enabling faster turnaround times, making it a favored choice among manufacturers looking to improve operational efficiency and meet customer demands more effectively. As these trends progress, the industrial printing landscape will continue to evolve, paving the way for smarter and more sustainable production processes.

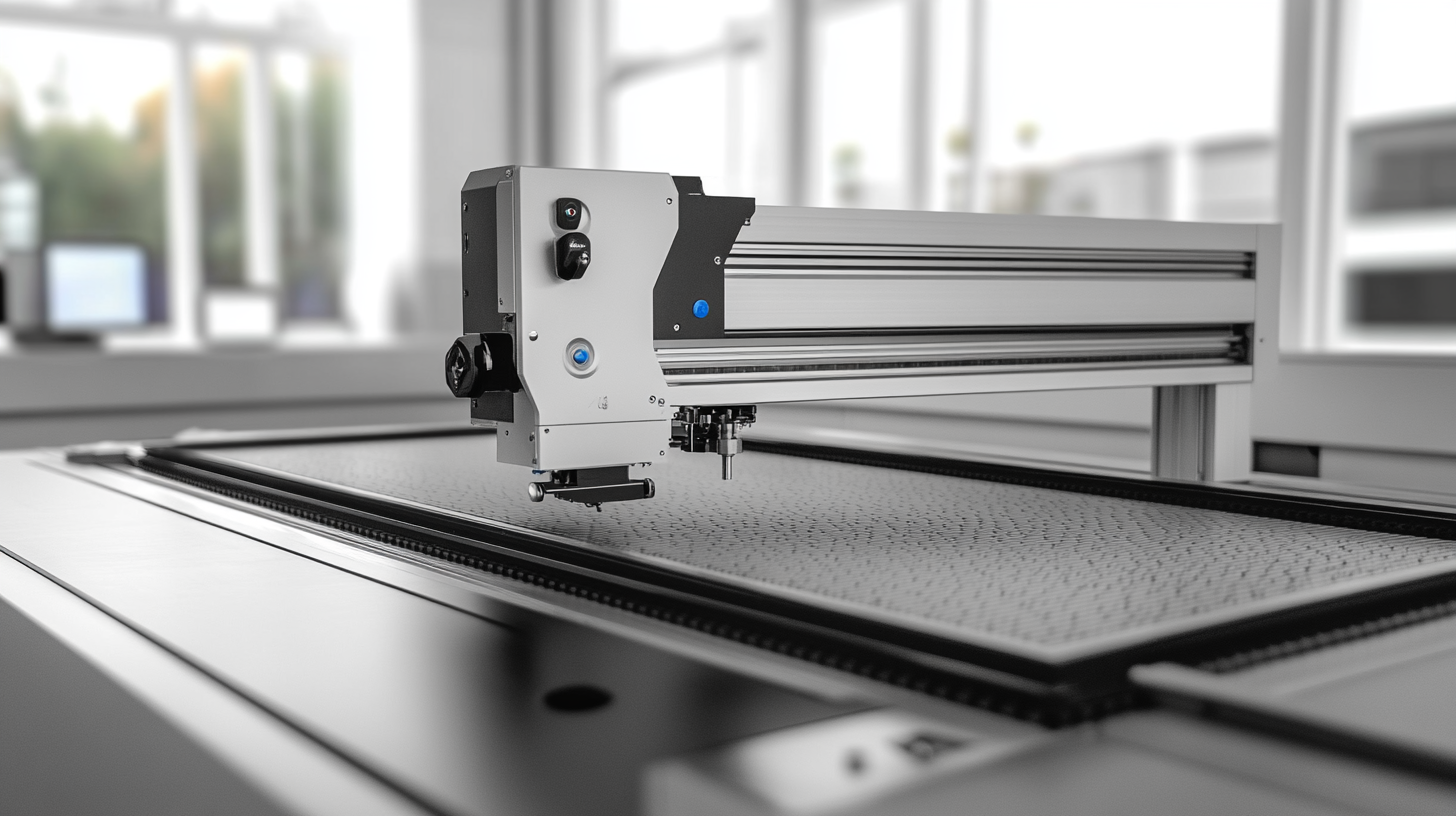

Key Features to Look for in Industrial Printers for Optimal Efficiency

In 2023, the field of industrial printing continues to evolve rapidly, with key features that enhance efficiency becoming increasingly vital for manufacturers. One of the primary aspects to consider when selecting an industrial printer is the level of automation it offers. Systems like the AMPro Sieve Station are designed to streamline powder recovery processes, significantly boosting printing efficiency by minimizing material waste—a crucial factor in reducing operational costs and maximizing productivity in additive manufacturing setups.

Another vital feature is the ability to handle advanced materials. With the growing interest in industrial-grade carbon fiber composites, as demonstrated by companies like 9T Labs, industrial printers must be capable of working with diverse material types to meet the demands of modern manufacturing. Reports indicate that production using metal 3D printers surged in 2021, with several enterprises surpassing annual shipping volumes of thousands of units, indicating a robust market for versatile printing solutions.

Additionally, scalability plays a significant role in the selection of industrial printers. Manufacturers require machines that not only maintain high quality but can also scale operations seamlessly. As industries adapt to more complex designs and increased production rates, printers must be equipped to handle varying load demands without compromising on performance. Investing in an industrial printer with these key features will undoubtedly lead to more optimal efficiency in production environments.

Comparison of Leading Industrial Printers: Performance and Reliability Metrics

When it comes to industrial printers, performance and reliability are paramount for manufacturers seeking to enhance their production efficiency. According to a report published by Smithers Pira, the global industrial printing market was valued at over $15 billion in 2022, with projections indicating a steady annual growth rate of 4.5% through 2027. This underscores the rising demand for robust printing solutions that can deliver high-quality results consistently.

In evaluating the leading industrial printers in the market, metrics such as print speed, durability, and operational uptime are critical. For example, the Canon PRO 4000 series boasts a remarkable print speed of up to 24.5 square meters per hour, making it an excellent choice for time-sensitive projects. Reliability, quantified through mean time between failures (MTBF), also plays a crucial role. On average, top-tier industrial printers have an MTBF of around 7,000 hours, ensuring minimal disruption in production.

Moreover, advancements in print technology have contributed to enhanced print quality and resource efficiency. The Epson SureColor series leverages PrecisionCore technology, producing 99% accurate colors with reduced ink wastage, thus cutting operational costs by approximately 30%. This aligns with industry trends where manufacturers are increasingly prioritizing sustainability while maintaining high standards in productivity and output quality.

By adopting printers that excel in performance and reliability, businesses can not only improve their operational efficiency but also respond swiftly to dynamic market demands, ultimately positioning themselves for success in an ever-competitive landscape.

Exploring the Impact of Print Speed on Production Efficiency and Costs

In the fast-paced world of industrial manufacturing, print speed is not just a metric; it is a critical factor that influences overall production efficiency and cost management. According to a recent report by Smithers Pira, printers capable of delivering speeds exceeding 100 meters per minute can increase a facility’s output by approximately 30%. This boost in speed directly translates to reduced operational costs, as companies can produce higher volumes in shorter timeframes, maximizing their investment in machinery and labor.

Moreover, the relationship between print speed and production efficiency extends to the quality of output. High-speed printers, when integrated with advanced technology like enhanced ink formulations and precise calibration systems, maintain consistent quality while improving turnaround times. For instance, a study by IDTechEx indicates that manufacturers utilizing variable data printing with speeds averaging 200 meters per minute have seen a 20% reduction in waste material, further optimizing their resource utilization and lowering costs.

Investing in high-speed industrial printing solutions is increasingly becoming essential. In 2023, industries leveraging these high-performance printers are projected to see an upsurge in profitability, as faster production cycles mean quicker market responses and enhanced competitiveness. As organizations navigate the complexities of supply chain demands and customer expectations, prioritizing print speed in their operational strategies will undoubtedly play a pivotal role in defining their success.

Sustainability in Industrial Printing: Eco-Friendly Technologies and Practices

In the ever-evolving landscape of industrial printing, sustainability has emerged as a key focus, driving innovations and practices that minimize environmental impact. As industries increasingly adopt eco-friendly technologies, we witness a shift towards greener printing solutions. The adoption of improved toner technology stands out as a significant advancement, allowing for reduced emissions and waste. Companies are now employing more efficient processes that not only lessen the carbon footprint but also enhance output quality.

Moreover, the development of sustainable polymers is revolutionizing the materials used in printing. Derived from renewable and recycled resources, these polymers offer a promising alternative to conventional materials, ensuring that printers can operate with lower environmental costs. This shift toward eco-friendly materials aligns with broader sustainability goals, allowing businesses to contribute positively to the environment while maintaining production efficiency.

Companies like HP are leading the charge in environmental innovation, showcasing how sustainable practices can be integrated into industrial operations. By implementing forest restoration programs and committing to responsible sourcing, they are setting new benchmarks for eco-conscious manufacturing. This leadership in sustainability is crucial as it not only enhances corporate responsibility but also encourages other businesses in the industry to follow suit, fostering a culture of environmental stewardship. The future of industrial printing appears not only more efficient but also significantly more sustainable, a change that benefits businesses, customers, and the planet alike.