Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register now5 Compelling Reasons to Choose Industrial Inkjet Printing for Your Business Needs

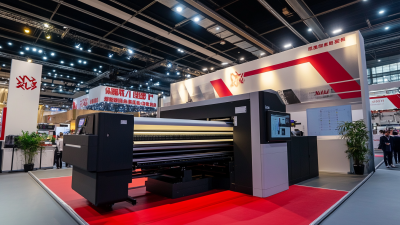

In today's fast-paced industrial landscape, the need for efficient and high-quality printing solutions has never been more critical. Among the various options available, Industrial Inkjet Printing stands out as a powerful technology that caters to a diverse range of business needs. From packaging and labeling to signage and product markings, this printing method offers unparalleled versatility and speed, enabling companies to enhance their operational efficiency.

Furthermore, as industries strive for sustainability and cost-effectiveness, Industrial Inkjet Printing emerges as a frontrunner, providing eco-friendly ink options and reducing waste. In this blog, we will delve into five compelling reasons why integrating Industrial Inkjet Printing into your business strategy can drive innovation, improve productivity, and ultimately lead to greater success in today’s competitive market.

The Advantages of Industrial Inkjet Printing for Modern Businesses

Industrial inkjet printing has emerged as a powerful solution for modern businesses, offering several distinct advantages that can significantly enhance operational efficiency. According to Smithers Pira's 2020 report, the global inkjet printing market is projected to grow to $109 billion by 2024, driven largely by advancements in technology and increasing demand for customization. This growth is a testament to the capability of industrial inkjet printing to deliver high-quality prints at remarkable speeds, making it an ideal choice for businesses looking to streamline their production processes.

One of the most compelling advantages of industrial inkjet printing is its versatility in substrate compatibility. Unlike traditional printing methods, inkjet can print on a wide range of materials, from corrugated cardboard to flexible films, without the need for extensive setup changes. A study from the Printing Industries Association showed that companies utilizing inkjet technology reported a 30% reduction in material waste, attributed to its precise application of ink. Additionally, the shift toward digital printing allows businesses to respond rapidly to market trends and consumer demands, enabling shorter production runs without incurring hefty costs, thereby optimizing their supply chain management.

Understanding the Technology Behind Industrial Inkjet Printing

Industrial inkjet printing is at the forefront of modern manufacturing, offering versatility and efficiency that traditional printing methods struggle to match. At the core of this technology lies the precision of droplet formation, which enables high-quality prints on various materials. Utilizing piezoelectric or thermal inkjet technology, industrial printers can dispense ink droplets with remarkable accuracy, allowing for intricate designs and detailed graphics that enhance product appeal. This capability not only supports onboarding processes in manufacturing but also reduces waste by ensuring that every drop of ink counts.

Moreover, industrial inkjet printers are designed for high-speed production environments, capable of printing long runs without sacrificing quality. Their ability to quickly switch between different inks or colors further boosts their adaptability, enabling businesses to meet diverse customer demands without extensive setup times. This flexibility, combined with reduced operational costs compared to traditional printing methods, positions industrial inkjet printing as a valuable solution for businesses looking to innovate and streamline their printing processes. Understanding these technological advancements can help businesses leverage industrial inkjet printers to optimize their production lines and enhance their overall market presence.

Cost-Effectiveness: Saving Money Without Compromising Quality

Industrial inkjet printing is rapidly becoming the go-to solution for businesses looking to enhance their production efficiency while balancing quality and cost. With the current financial strains many face, such as the findings from the Ludwig Institute indicating that only 40% of Americans can afford a minimal quality of life, companies must prioritize smart investments. Industrial inkjet printing offers a cost-effective solution, enabling businesses to achieve high-quality outputs without overspending.

One major advantage is its ability to reduce material wastage. By utilizing precision printing techniques, companies can optimize their use of ink and materials, leading to significant savings over time. Additionally, many businesses find that the durability and versatility of industrial inkjet printers provide a greater return on investment compared to traditional methods, ensuring that quality is never compromised for cost.

**Tips for Cost-Effectiveness:**

1. **Evaluate Total Cost of Ownership:** Consider the lifetime costs of machines, including maintenance and materials, rather than just the initial purchase price.

2. **Optimize Your Workflow:** Streamlining your production process can minimize waste and enhance efficiency, directly impacting your bottom line.

3. **Invest in Training:** Establishing a well-trained workforce ensures that your team can maximize the capabilities of industrial inkjet technology, ultimately leading to better quality outputs at lower costs.

Versatility: How Inkjet Printing Meets Diverse Industry Needs

Industrial inkjet printing has become a frontrunner in various sectors due to its remarkable versatility. One of the primary advantages of inkjet technology is its ability to adapt to a wide range of materials and applications. From textiles to packaging and signage, inkjet printing can effortlessly handle different substrates and deliver high-quality results. This flexibility allows businesses to experiment with diverse designs and finishes, meeting the unique demands of their industries without the need for extensive modifications in their production processes.

Industrial inkjet printing has become a frontrunner in various sectors due to its remarkable versatility. One of the primary advantages of inkjet technology is its ability to adapt to a wide range of materials and applications. From textiles to packaging and signage, inkjet printing can effortlessly handle different substrates and deliver high-quality results. This flexibility allows businesses to experiment with diverse designs and finishes, meeting the unique demands of their industries without the need for extensive modifications in their production processes.

Moreover, inkjet printing is particularly beneficial for short runs and customized products. Companies no longer need to commit to large production volumes to achieve efficiency; instead, they can produce smaller batches while maintaining quality. This is especially advantageous in industries like fashion and marketing, where personalization and quick turnaround times are essential. The ability to swiftly switch between different inks and formulations further enhances the practicality of inkjet technology, allowing businesses to innovate and respond dynamically to changing market trends.

Enhancing Productivity: Speed and Efficiency in Printing Operations

In today's fast-paced manufacturing environment, enhancing productivity is crucial, and industrial inkjet printing stands out as a game-changer. According to a report by Smithers Pira, the industrial inkjet market is projected to grow at a CAGR of 8.5% between 2021 and 2026, driven by its unmatched speed and efficiency in various applications.

Featuring advanced automation and high-speed capabilities, industrial inkjet systems can produce prints at speeds of up to 150 meters per minute. This rapid output significantly reduces downtime, allowing businesses to meet tight deadlines and respond swiftly to market demands.

Moreover, the efficiency of industrial inkjet printing extends beyond speed. A survey conducted by the Association for Printing Technologies revealed that companies adopting inkjet technology reported a 20-30% improvement in overall workflow efficiency. This increase is largely attributed to the reduced need for setup time and quick changeovers, enabling manufacturers to transition between different jobs with minimal interruption. As a result, businesses can optimize their production schedules, minimizing waste and maximizing resource utilization. Embracing industrial inkjet printing could be the key to elevating productivity levels while staying competitive in an ever-evolving market landscape.

Related Posts

-

Unlocking Global Opportunities at the 137th Canton Fair with Industrial Inkjet Printing Innovations

-

Understanding the Differences Between Continuous Inkjet Printers and Other Coding Technologies

-

Innovative Examples of Inkjet Coder Applications Driving Efficiency in Modern Manufacturing

-

Global Ink Cartridges Market Outlook 2025: Trends, Challenges, and Success Stories

-

Exploring the Future of Cij Printers: Trends and Strategies for Global Buyers in 2025

-

Forecasting the Future of Best Coding Printers in the Market by 2025 Insights and Trends