Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowQuality-Centric Manufacturing: Unveiling the World's Best Code Printer from China

In the rapidly evolving landscape of manufacturing, the demand for high-quality code printers has surged significantly, driven by the increasing need for precise labeling and tracking in various industries. According to a report by MarketsandMarkets, the global coding and marking market is projected to reach USD 6.8 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth reflects a pivotal shift towards quality-centric manufacturing, emphasizing the importance of reliable and efficient printing solutions. As businesses seek to optimize their production processes and enhance product traceability, selecting a reputable manufacturer, particularly from China—known for its robust industrial capabilities—becomes essential. Thus, understanding the key attributes of premium code printers and the factors influencing manufacturer quality is crucial for organizations aiming to stay competitive in this dynamic market.

The Evolution of Code Printing Technology in China

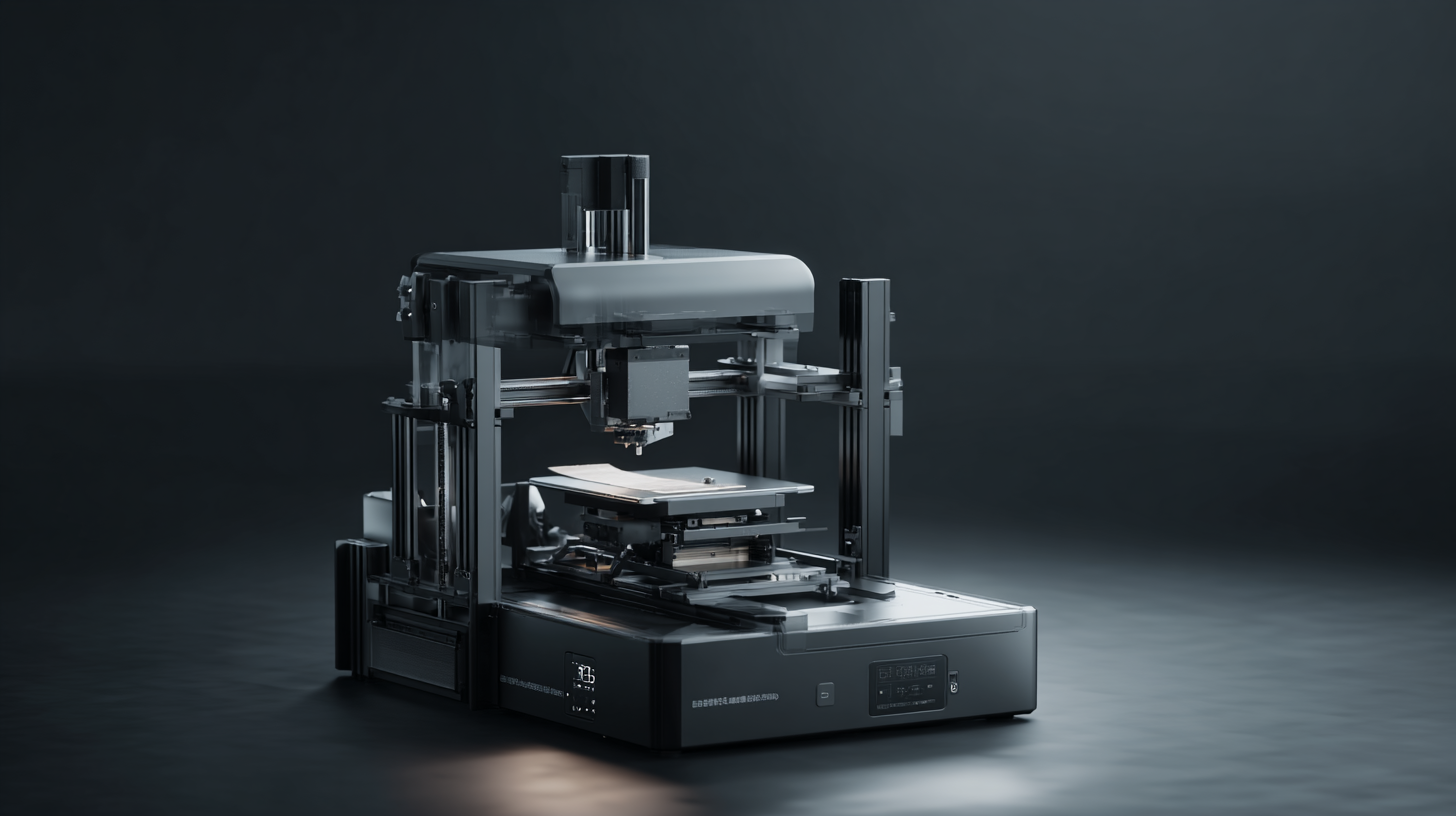

Over the past few decades, code printing technology in China has undergone a remarkable evolution, driven by a relentless pursuit of quality and innovation. Initially, the production of code printers was characterized by basic inkjet systems that struggled with consistency and reliability. However, advancements in materials and automation have transformed the landscape. Manufacturers began integrating cutting-edge technologies such as laser printing and thermal transfer, which not only enhanced precision but also extended the lifespan of the printers.

As the industry matured, Chinese manufacturers took a proactive approach to meet global standards, resulting in the emergence of world-class code printers. These new models are designed with user-friendliness in mind, boasting features like intuitive interfaces and smart connectivity. Furthermore, the rise of Industry 4.0 has spurred manufacturers to incorporate IoT capabilities, enabling seamless data tracking and real-time monitoring. This transformation has positioned China as a leader in quality-centric manufacturing, catering to an increasing demand for efficient and high-performance code printing solutions worldwide.

Key Features That Define the Best Code Printers for Quality-Centric Manufacturing

In the realm of quality-centric manufacturing, selecting the right code printer is paramount to ensuring product integrity and enhancing operational efficiency. The best code printers tend to embody several pivotal features that set them apart in the industry. For instance, according to a recent report by Smithers Pira, over 60% of manufacturers prioritize print quality and speed, making these aspects critical when evaluating code printers. Advanced inkjet technology, which offers high-resolution output up to 600 dpi, enables manufacturers to produce sharp, legible codes even on challenging substrates. This feature not only satisfies regulatory requirements but also improves consumer safety by minimizing misidentification of products.

Moreover, the adaptability of the printer plays a crucial role in diverse manufacturing environments. Models equipped with smart connectivity options and user-friendly interfaces are increasingly favored, as highlighted by the 2022 Manufacturing Technology Report, which states that 40% of manufacturers are integrating IoT solutions into their production lines. Flexibility in print size, style, and the ability to switch between various substrates without losing quality provides manufacturers with the versatility they need to stay competitive. By focusing on these features, industry leaders can achieve a seamless integration of quality control in their manufacturing processes, ensuring they meet both internal standards and external regulatory guidelines.

How to Choose the Right Code Printer for Your Manufacturing Needs

When selecting the right code printer for your manufacturing needs, it's crucial to assess several factors that can significantly impact efficiency and product quality. First, consider the type of printing technology that aligns with your production environment. Options like thermal inkjet, laser, and continuous inkjet printers each have distinct benefits. Thermal inkjet printers are known for their simplicity and high-quality print resolution, making them ideal for lighter workloads. In contrast, continuous inkjet printers offer greater speed and durability, suitable for high-volume production workflows.

Another important aspect to evaluate is the printer's compatibility with various substrates. Ensure the code printer can effectively print on the materials you frequently use, whether it's plastic, cardboard, metal, or glass. Additionally, examine the maintenance requirements of the printer, as ease of upkeep can save both time and money in the long run. Potential downtime from maintenance issues can hamper production, so choosing a reliable and low-maintenance model will enhance overall operational efficiency. By focusing on these critical aspects, manufacturers can seamlessly integrate the best code printer into their processes, driving quality and productivity forward.

Quality-Centric Manufacturing: Unveiling the World's Best Code Printer from China - How to Choose the Right Code Printer for Your Manufacturing Needs

| Printer Model | Printing Technology | Print Speed (mm/s) | Resolution (dpi) | Price (USD) |

|---|---|---|---|---|

| Model A1 | Thermal Inkjet | 150 | 600 | 200 |

| Model B2 | Laser | 120 | 1200 | 350 |

| Model C3 | Continuous Inkjet | 180 | 300 | 250 |

| Model D4 | Drop-On-Demand | 130 | 480 | 280 |

| Model E5 | Thermal Transfer | 110 | 300 | 230 |

Maintaining Quality Standards: Best Practices for Code Printer Operation

In the rapidly evolving landscape of manufacturing, maintaining quality standards is crucial, especially when it comes to code printers. These machines play a significant role in ensuring that products are accurately labeled and compliant with various regulations. To operate effectively, it is essential to establish best practices that prioritize precision and reliability. Regular maintenance checks, for instance, are vital in detecting potential issues before they escalate, thereby ensuring uninterrupted production.

Moreover, investing in high-quality ink and materials is equally important. Poor-quality consumables can lead to smudged prints or faded codes, ultimately compromising product traceability. Implementing a robust training program for operators is another key practice that pays dividends. Well-trained personnel are more adept at troubleshooting and can make informed decisions on optimizing printer settings to achieve superior results. By focusing on these best practices, manufacturers can enhance their operational efficiency and maintain the high-quality standards expected in today's competitive market.

Exploring Innovations in Code Printing for Enhanced Production Efficiency

In today's competitive manufacturing landscape, the role of code printing in production efficiency cannot be overstated. Innovations in code printing technology are paving the way for improved accuracy, speed, and integration into existing production lines. The latest advancements allow manufacturers to produce high-quality prints that are essential for tracking and compliance, ensuring products are not only market-ready but also compliant with regulations.

One of the most significant developments in this field has been the rise of high-performance code printers from China. These machines are designed with cutting-edge technology, focusing on reliability and ease of use. By incorporating features such as quick-drying inks and automatic adjustment for different materials, these printers significantly reduce downtime. The ability to print on various surfaces and shapes seamlessly enhances production versatility, enabling manufacturers to meet diverse market demands with efficiency and precision.