Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowHow to Optimize Production Efficiency with an Industrial Inkjet Printer

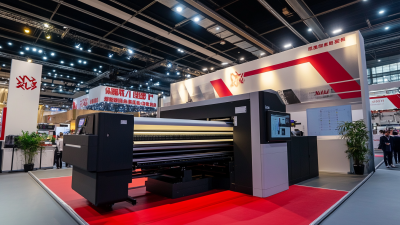

In today's fast-paced manufacturing environment, optimizing production efficiency is paramount for businesses striving to maintain a competitive edge. One critical component of this optimization is the use of an Industrial Inkjet Printer, a technology that has revolutionized the way products are marked and coded. According to a report by Smithers Pira, the global market for industrial inkjet printing is projected to reach $3 billion by 2024, reflecting a compound annual growth rate of over 5%. This growth underscores the increasing adoption of industrial inkjet printers across various sectors, including packaging, textiles, and automotive, where speedy application and versatility are essential. By effectively leveraging the capabilities of an Industrial Inkjet Printer, companies can enhance their production workflows, reduce waste, and significantly lower operational costs, making it a vital tool for those looking to improve efficiency in their manufacturing processes.

In today's fast-paced manufacturing environment, optimizing production efficiency is paramount for businesses striving to maintain a competitive edge. One critical component of this optimization is the use of an Industrial Inkjet Printer, a technology that has revolutionized the way products are marked and coded. According to a report by Smithers Pira, the global market for industrial inkjet printing is projected to reach $3 billion by 2024, reflecting a compound annual growth rate of over 5%. This growth underscores the increasing adoption of industrial inkjet printers across various sectors, including packaging, textiles, and automotive, where speedy application and versatility are essential. By effectively leveraging the capabilities of an Industrial Inkjet Printer, companies can enhance their production workflows, reduce waste, and significantly lower operational costs, making it a vital tool for those looking to improve efficiency in their manufacturing processes.

Common Challenges in Industrial Inkjet Printing and Their Solutions

Industrial inkjet printing offers significant potential for enhancing

production efficiency; however, several common challenges must be addressed to unlock its full capabilities.

One of the primary issues is achieving consistent print quality. Inconsistent ink droplet sizes and

placement can lead to defects in the final product. To reduce this problem, manufacturers can implement

regular maintenance protocols and invest in

high-precision printing heads that deliver superior droplet control, ensuring high-quality output across

various substrates.

Industrial inkjet printing offers significant potential for enhancing

production efficiency; however, several common challenges must be addressed to unlock its full capabilities.

One of the primary issues is achieving consistent print quality. Inconsistent ink droplet sizes and

placement can lead to defects in the final product. To reduce this problem, manufacturers can implement

regular maintenance protocols and invest in

high-precision printing heads that deliver superior droplet control, ensuring high-quality output across

various substrates.

Another challenge involves the compatibility of inks with different

materials. Not all inks perform well on all surfaces, which can result in poor adhesion and fading over time.

To tackle this, developing a comprehensive understanding of ink formulations and substrate interactions

is essential. Using tailored inks designed for specific applications can enhance performance and longevity,

while also reducing waste caused by reprints. Embracing advancements in ink technology will promote

better adhesion and durability, making industrial inkjet printing a more reliable option for manufacturers

looking to optimize their production processes.

Effective Maintenance Practices for Maximizing Inkjet Printer Life

Effective maintenance practices are crucial for maximizing the lifespan of industrial inkjet printers, ensuring not only optimal performance but also significant cost savings. According to a report from Smithers Pira, the global inkjet printing market is set to reach $45 billion by 2027, underscoring the value of maintaining high operational efficiency in production environments. Regular maintenance routines such as cleaning print heads, checking ink levels, and calibrating print settings can prevent malfunction and downtime. Research indicates that proactive maintenance can reduce unexpected printer failures by up to 40%, significantly enhancing productivity.

Additionally, keeping a detailed maintenance log can help identify patterns that signal potential issues before they escalate. A study conducted by the Association for Printed Electronics demonstrated that printers with structured maintenance schedules extend their operational life by an average of 30%. Implementing these practices not only prolongs the printer's lifespan but also ensures consistent print quality and ink usage, leading to better overall efficiency. By prioritizing maintenance, companies can enhance production capabilities while reducing the total cost of ownership for inkjet printing systems.

Choosing the Right Ink and Substrate to Avoid Print Quality Issues

Choosing the right ink and substrate is crucial for optimizing production efficiency in industrial inkjet printing. A mismatch between ink and substrate can lead to significant print quality issues, such as poor adhesion, smudging, or fading. For instance, selecting a substrate that is not compatible with the ink type can result in suboptimal performance, leading to increased waste and downtime. It's essential to conduct thorough testing to ensure that the chosen ink not only adheres well to the substrate but also maintains vibrant colors and sharp details.

When optimizing ink and substrate selection, consider the specific requirements of your project. Factors such as the printing environment, desired finish, and durability should guide your choices. For example, certain inks are better suited for outdoor applications due to their UV resistance, while others may excel in indoor settings. Additionally, printing on various substrates—like plastics, metals, or carton board—requires inks formulated to bond effectively. By carefully evaluating these elements, you can enhance overall print quality and streamline production processes, ultimately leading to improved efficiency and reduced costs.

Production Efficiency Optimization with Industrial Inkjet Printers

Understanding Print Speed vs. Quality: Finding the Right Balance

When optimizing production efficiency with an industrial inkjet printer, understanding the dynamic between print speed and print quality is crucial. Striking the right balance can impact not only the final product but also the overall workflow and resource management in your production line. In high-demand environments, faster print speeds can significantly enhance throughput; however, sacrificing quality can lead to increased waste and rework costs.

**Tip 1:** Conduct regular assessments of your production needs. Analyze the demand for speed against your quality standards to identify optimal print settings. This evaluation can help you adjust the printer's configuration to achieve better results without compromising efficiency.

**Tip 2:** Experiment with different substrates and inks. Certain combinations can allow for higher speeds without detrimental effects on print quality. Testing under real production conditions will provide insights into the best practices for your specific requirements.

Incorporating advanced monitoring systems can also play a pivotal role in maintaining this balance. Real-time feedback on print quality metrics can help operators make informed decisions on the fly, ensuring that efficiency is maximized while meeting quality expectations.

Integrating Industrial Inkjet Printers into Existing Production Lines

Integrating industrial inkjet printers into existing production lines offers businesses a pathway to significant efficiency gains. As the global market for industrial inkjet printers is projected to skyrocket to $11.22 billion by 2031, the adoption of these versatile printers is becoming increasingly attractive to manufacturers looking to enhance their operations. A key advantage of industrial inkjet printing is its ability to seamlessly integrate with current production setups, providing flexibility in various applications, from packaging to labeling.

Recent advancements in inkjet technology, such as specialized printing units designed for easy integration, further facilitate this process. These innovations allow for streamlined workflows, minimizing downtime and improving output quality. With companies looking to optimize their production efficiency, integrating intelligent automation alongside industrial inkjet systems can unlock substantial growth, ensuring that businesses stay ahead in the competitive landscape. Such tailored solutions not only improve productivity but also enhance the overall manufacturing process, positioning companies for future successes.

How to Optimize Production Efficiency with an Industrial Inkjet Printer - Integrating Industrial Inkjet Printers into Existing Production Lines

| Aspect | Before Integration | After Integration | Improvement (%) |

|---|---|---|---|

| Production Speed (units/hour) | 150 | 250 | 66.67% |

| Waste Rate (%) | 8 | 3 | 62.50% |

| Downtime (hours/week) | 10 | 2 | 80.00% |

| Maintenance Costs ($/month) | 1200 | 600 | 50.00% |

| Customer Satisfaction (%) | 75 | 92 | 22.67% |

Related Posts

-

The Comprehensive Handbook for Mastering Industrial Inkjet Printer Technology

-

Empowering Global Industries with Innovative Industrial Inkjet Printing Solutions

-

Unlocking Global Opportunities at the 137th Canton Fair with Industrial Inkjet Printing Innovations

-

Exploring Innovative Alternatives to Best Ink Cartridges for Cost Effective Printing

-

Effective Techniques for Maximizing Efficiency with the Best Coding Machine

-

5 Compelling Reasons to Choose the Best Ink Jet Solutions for Your Business Needs