Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowWhy Choose Stainless Steel Woven Wire Mesh for Your Projects?

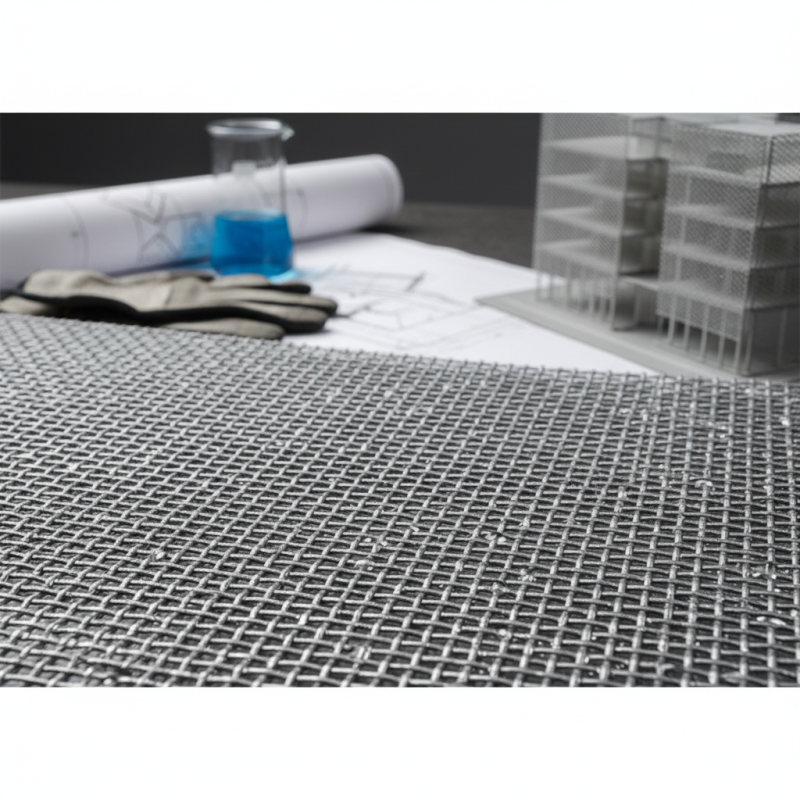

When considering material choices for engineering projects, the significance of stainless steel woven wire mesh is hard to overlook. Its unique properties make it suitable in diverse applications, from filtration to architectural designs. According to a report by the International Wire and Mesh Association, the demand for stainless steel mesh has grown by 15% annually, highlighting its importance in the industry.

Expert Dr. Andrew Kloss notes, “stainless steel woven wire mesh blends resilience with aesthetic appeal.” This statement reflects the dual nature of this material. It is strong and durable yet elegant enough for visible installations. Many industries, including food processing and pharmaceuticals, rely on stainless steel woven wire mesh for sanitary standards and structural integrity.

However, not all projects may require such high-end materials. Cost and project requirements can sometimes lead to suboptimal choices. It’s crucial to weigh the long-term benefits of investing in quality mesh against initial budget constraints. A thoughtful consideration of needs can prevent a project's success from being compromised.

Benefits of Stainless Steel Woven Wire Mesh in Construction Projects

Stainless steel woven wire mesh offers remarkable advantages for construction projects. Its durability stands out. Made from high-quality stainless steel, it resists corrosion and rust. This resistance ensures a longer lifespan for structures. In environments prone to moisture, this quality is crucial. Projects can thrive without frequent replacements.

Another key benefit is strength. The weave pattern provides a tight, sturdy structure. This mesh can withstand significant tension and pressure. It can support heavier loads than traditional materials. Additionally, it maintains its shape even under stress. Construction teams appreciate fewer failures during critical phases.

Versatility is another appealing factor. Stainless steel woven wire mesh adapts to various applications. It fits well in fencing, partitions, and filtration systems. However, not all projects may need such durable materials. Cost considerations may limit its use in some cases. Nonetheless, when durability and reliability are priorities, this material excels in construction.

Comparative Analysis: Stainless Steel vs. Other Wire Mesh Materials

When considering wire mesh materials, stainless steel stands out due to its superior properties. Compared to other materials, it offers excellent resistance to corrosion and deformation. This makes it ideal for various applications, especially in harsh environments. Other materials, like plastic or carbon steel, may degrade or warp sooner. Stainless steel maintains its integrity over time, providing reliable performance.

Tips: Always consider the environment where the mesh will be used. Ensure it can withstand specific chemical exposures. Regular maintenance can prolong its lifespan significantly.

Another point to ponder is the cost. Stainless steel might seem expensive initially, but it can save you money in the long run. Cheaper alternatives may require frequent replacements. Further, the strength-to-weight ratio of stainless steel can reduce the overall load on structures.

Tips: When choosing materials, factor in both initial investment and long-term costs. Weigh the tradeoffs before making a decision. Check for specific grades of stainless steel that suit your needs best.

Durability and Corrosion Resistance of Stainless Steel Mesh

Stainless steel woven wire mesh is valued for its durability and corrosion resistance. This material withstands harsh environments better than many alternatives. It is often used in construction, filtration, and agricultural applications. The longevity of stainless steel means fewer replacements, ultimately saving costs.

Corrosion occurs when metals react with moisture or chemicals. Stainless steel’s inherent properties prevent such reactions, maintaining its structural integrity. This makes it ideal for outdoor use. For instance, mesh used in coastal areas tends to resist saltwater corrosion. However, even stainless steel can develop surface rust in extreme conditions.

Choosing stainless steel wire mesh can be a wise decision. Yet, proper maintenance is still crucial. Regular cleaning can extend its life even further. Users should be aware that neglect can lead to issues over time. While it is a long-lasting option, no material is completely maintenance-free. Consideration of these factors is essential for optimal performance.

Applications of Stainless Steel Woven Wire Mesh in Various Industries

Stainless steel woven wire mesh is widely used across various industries for its durability and versatility. In agriculture, it serves as a protective barrier. Farmers use it to safeguard crops from pests. A recent report by the Agricultural Standards Institute indicated a 25% increase in crop yields when using durable mesh. This impact highlights the mesh's essential role in sustainable farming practices.

In the construction sector, stainless steel mesh provides safety and structural integrity. It is often found in architectural designs and as reinforcement in concrete structures. According to a Building Materials Association study, projects utilizing this type of mesh showed a 15% decrease in construction delays due to enhanced safety measures. Such data suggests it’s not just about aesthetics, but practicality as well.

The food and beverage industry also benefits from stainless steel woven wire mesh. It's used in filtration systems and processing equipment. Research from the Food Safety Council emphasizes that using stainless steel reduces contamination risks by 30%. This is significant, as hygiene is paramount in food production. Yet, the initial cost may deter some businesses from adopting such materials, presenting a challenge worth addressing.

Why Choose Stainless Steel Woven Wire Mesh for Your Projects? - Applications of Stainless Steel Woven Wire Mesh in Various Industries

| Industry | Application | Benefits |

|---|---|---|

| Food Processing | Filtering and sieving of food products | Corrosion resistant, easy to clean |

| Construction | Reinforcement in concrete structures | Strong and durable, long lifespan |

| Pharmaceutical | Mesh filters for drugs and laboratory processes | Non-reactive, maintains purity of products |

| Oil & Gas | Separation and filtration of fluids | High strength, withstands harsh environments |

| Mining | Screening and sorting of ores | Durable and resistant to wear |

Cost-Effectiveness and Longevity of Stainless Steel Mesh Solutions

When considering materials for projects, stainless steel woven wire mesh stands out for its cost-effectiveness. Unlike other materials, stainless steel offers great durability at a reasonable price. It resists corrosion and wear, making it ideal for long-term applications. The upfront investment may be higher, but the savings over time are substantial.

These mesh solutions also provide longevity. They can withstand harsh environments without degrading. Think of construction sites, where materials are often exposed to elements. Stainless steel maintains its integrity longer than alternatives. There are instances where less durable materials have failed, leading to costly replacements. This is a risk that stainless steel mitigates effectively.

However, not all stainless steel meshes are created equal. Some may have a higher initial cost but provide better performance. It’s essential to assess the specific needs of each project. The right choice can enhance efficiency and reduce future expenses, but this requires careful evaluation. Choosing wisely can lead to sustainable solutions that pay off in the long run.