Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowBest Surgical Instruments for Precision and Efficiency in Surgery?

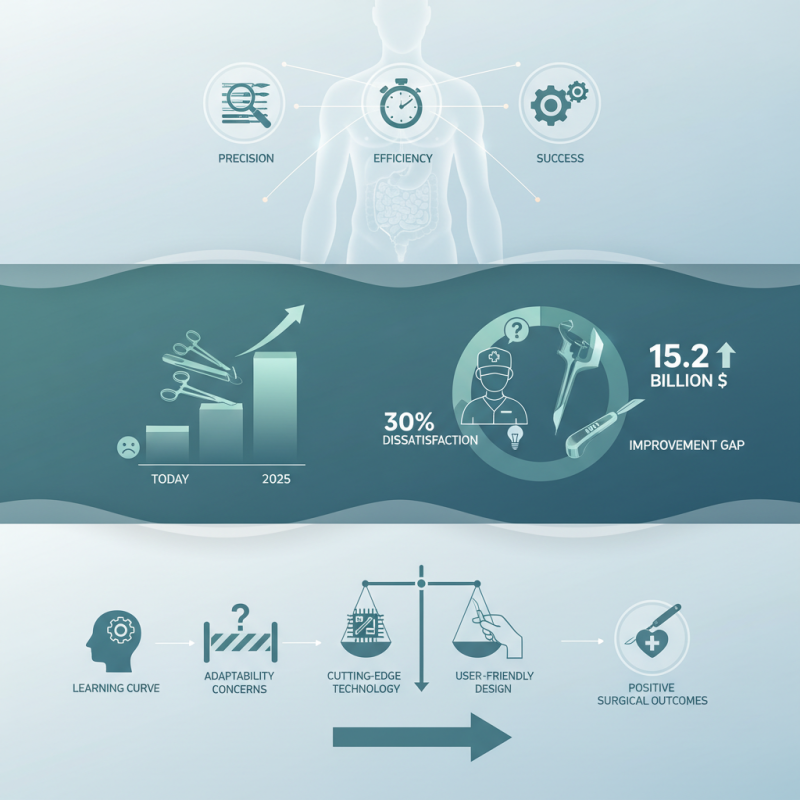

In the world of surgery, precision is paramount. The right Surgical Instruments can mean the difference between success and complications. According to a report by MarketsandMarkets, the surgical instrument market is projected to reach $15.2 billion by 2025, indicating a strong demand for high-quality tools. Industry expert Dr. Emily Carter emphasizes, "The effectiveness of a surgical procedure largely hinges on the instruments used."

However, not all surgical instruments are created equal. While some tools offer advanced functionality, others may fall short in ergonomic design or reliability. A study in the Journal of Surgical Research found that 30% of surgeons report dissatisfaction with instrument performance, leading to potential frustration during operations. This gap highlights a significant area for improvement in instrument design and manufacturing.

The pursuit of efficiency must also consider the learning curve associated with new instruments. Many surgeons hesitate to adopt innovative tools due to concerns about adaptability. Hence, the surgical instrument industry faces a significant challenge: balancing cutting-edge technology with user-friendly design, ensuring all instruments contribute positively to surgical outcomes.

Essential Characteristics of Surgical Instruments for Precision

Precision in surgery relies heavily on the quality of surgical instruments. These tools must exhibit durability and sharpness to meet the demands of various procedures. A well-designed scalpel can drastically reduce tissue trauma, which enhances patient recovery. Conversely, a dull blade can lead to complications and prolonged healing times.

Ergonomics is another vital characteristic. Instruments should align comfortably with the surgeon's hand. An inconvenient grip can lead to fatigue and decreased precision. An example is tweezers: they should have the perfect tension. Instruments that are too tight or too loose can affect the surgeon's control during critical tasks.

Material choice directly impacts performance too. High-quality stainless steel is commonly preferred due to its strength and resistance to corrosion. However, cost considerations can sometimes lead to the use of lower-grade materials, which may compromise the effectiveness. This raises questions about balancing quality and affordability in surgical settings.

Best Surgical Instruments for Precision and Efficiency in Surgery

This chart illustrates the essential characteristics of various surgical instruments that enhance precision and efficiency in surgical procedures. The data represents the average rating (out of 10) based on precision, efficiency, and usability from a survey of surgical professionals.

Types of Surgical Instruments Commonly Used in Modern Surgery

Surgery relies on a variety of specialized instruments designed for precision and efficiency. Scalpels, for instance, are critical for making incisions. Their sharp blades allow surgeons to navigate tissues easily. They come in many sizes and shapes, each suited for specific tasks. However, not all scalpels are created equal. Choosing the wrong one can lead to complications.

Forceps are another vital tool in surgery. They help grasp and manipulate tissues during procedures. Some are designed for delicate operations, while others are sturdier for heavier tasks. The touch and feel of forceps can significantly impact performance. Incorrect handling might result in unintentional damage.

Scissors also play a crucial role, particularly in cutting sutures or tissues. Surgical scissors vary in design, promoting versatility. Yet, their effectiveness depends on the surgeon's skill. A slight miscalculation can alter the outcome. Overall, selecting the right instruments and mastering them takes time. It demands ongoing reflection and practice to optimize surgical performance.

Materials and Technologies Enhancing Surgical Instrument Performance

Surgical instruments play a vital role in modern medicine. The materials used in these tools significantly impact their performance. Stainless steel, often favored, is durable and easy to sterilize. However, it tends to be heavier than other options. Lightweight alternatives, like titanium, are gaining popularity but can be more costly.

Technological advancements are revolutionizing instrument design. For instance, some instruments now incorporate smart technology. This allows surgeons to track usage and performance data in real time. However, the integration of tech must be seamless. Complicated interfaces can frustrate users and hinder the surgical process.

On the performance side, coatings can enhance care. Non-stick surfaces help reduce tissue damage and promote healing. Yet, some coatings may wear off too quickly during procedures. This raises questions about longevity and effectiveness. Overall, the quest for the best surgical instruments continues, balancing precision and efficiency with material performance.

Best Practices for Maintaining Surgical Instrument Efficiency

Maintaining surgical instruments is critical for efficiency. Cleanliness is essential. Regularly sterilizing tools reduces infection risks. It’s beneficial to follow specific protocols. Use the right cleaning solutions for different materials. Some instruments may require a delicate touch. Overzealous cleaning can damage them.

Proper handling is equally important. Train all staff on instrument use. Incorrect handling can lead to wear and tear. Always check instruments for defects before procedures. A simple inspection can prevent mishaps. Staff should be encouraged to communicate any issues observed.

Storage matters too. Organize instruments logically in sterile spaces. Proper storage helps in quick retrieval. Instruments poorly stored might get misplaced or damaged. Regular audits of surgical tools can reveal patterns and areas for improvement. Reflect on current practices to identify gaps and enhance overall efficiency.

Future Trends in Surgical Instrument Design and Usage

The future of surgical instrument design is evolving rapidly. Precision and efficiency are becoming the core focus. Innovations aim to enhance outcomes while reducing operation times. According to recent reports, minimally invasive surgeries are on the rise, projected to grow by 10% annually. Surgeons are increasingly favoring instruments that provide better control and visibility.

Smart surgical instruments are gaining traction. These tools often integrate sensors to track performance in real-time. It allows for adjustments on the spot, increasing accuracy. However, there is a catch. Dependence on technology raises questions about training and reliability. Many surgeons prefer the tactile feedback of traditional tools.

Tips: Always consider the ergonomics of surgical instruments. Instruments should feel comfortable to hold and easy to manipulate. Regularly evaluate new tools for effectiveness. Relying solely on tech can lead to oversight. Keep an open dialogue with peers on what works best in the field.

Best Surgical Instruments for Precision and Efficiency in Surgery

| Instrument Type | Material | Precision Rating | Efficiency Rating | Future Trend |

|---|---|---|---|---|

| Scalpel | Stainless Steel | 9.5 | 8.0 | Smart Blade Technology |

| Forceps | Titanium | 9.0 | 8.5 | Ergonomic Design |

| Scissors | Carbon Steel | 9.2 | 8.0 | Self-sharpening Edges |

| Electrocautery | Aluminum | 9.8 | 9.0 | Wireless Operation |

| Suction Device | Polypropylene | 9.5 | 8.8 | Smart Sensor Technology |