Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register now2026 Best Stainless Steel Wire Mesh Options for Your Needs?

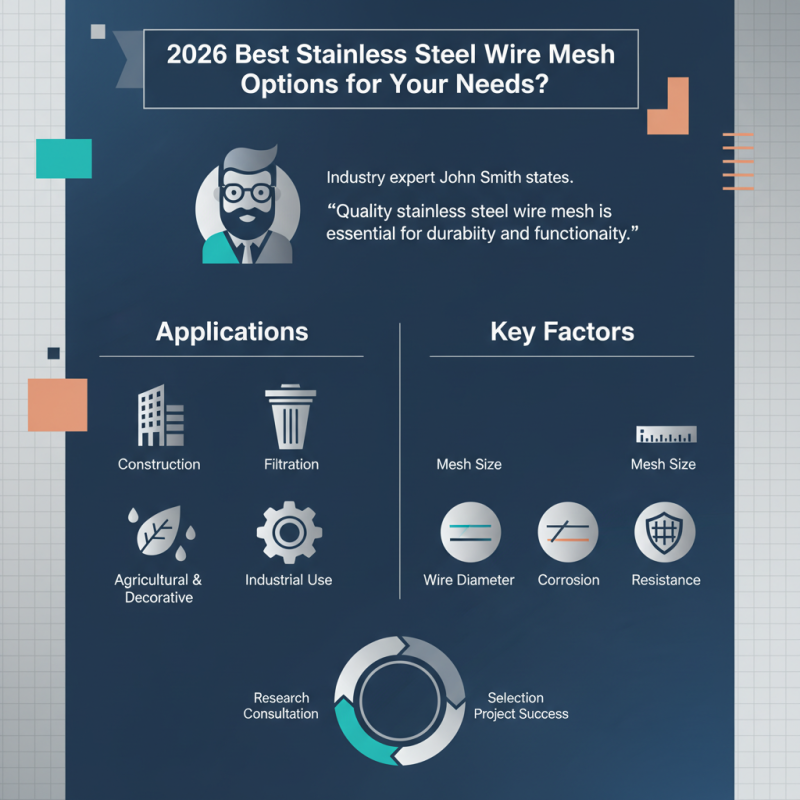

When it comes to selecting the best stainless steel wire mesh, the choices can be overwhelming. Industry expert John Smith states, “Quality stainless steel wire mesh is essential for durability and functionality.” This highlights the importance of understanding your specific needs before making a decision.

stainless steel wire mesh is widely used in various applications, from construction to filtration. Each project requires different specifications. Consider factors like mesh size, wire diameter, and corrosion resistance. These details can significantly affect the performance of the mesh.

However, finding the right option isn’t always straightforward. Many products claim to be the best, but sometimes they fall short in real-world applications. It's crucial to do thorough research and possibly seek guidance. The right stainless steel wire mesh can make all the difference in achieving your project’s goals.

Types of Stainless Steel Wire Mesh and Their Applications

Stainless steel wire mesh comes in various types, each serving unique applications. The most common type is welded wire mesh. This option features strong joints and is used in construction and fencing. It provides durability for outdoor use. However, it can be heavy, which may not suit lighter projects.

Another popular type is woven wire mesh. This mesh offers flexibility and is often used in filtration systems. It allows for effective liquid and gas separation. However, its adaptability may lead to wear and tear after prolonged use. Finding the right balance between flexibility and durability can be challenging.

Lastly, there’s expanded metal mesh. It’s created from a single sheet of metal and is perfect for applications requiring airflow and visibility. It's often used in security applications. However, its design can sometimes compromise structural integrity in high-stress situations. Exploring these options helps identify the best choice for specific needs.

Factors to Consider When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several factors come into play. The type of stainless steel is crucial. Different grades offer varying resistance to corrosion. Consider the environment where the mesh will be used. Does it face harsh chemicals or saltwater? This decision impacts longevity.

Mesh opening sizes also matter. Smaller openings may be needed for filtration purposes. Conversely, larger openings can improve airflow and visibility. The desired mesh density influences these choices as well. You might want lightweight mesh for easy installation. However, remember that durability might be compromised.

Tips: Always visualize the application before purchasing. Sketch your project to determine what you need. It's also wise to consult professionals if uncertain. Remember, trying to save costs on low-quality products can lead to greater expenses later. Pay attention to the wire diameter; thicker wires generally offer more strength but increase weight. Think about how you will handle the mesh during installation. Proper handling can prevent damage and improve overall results.

2026 Best Stainless Steel Wire Mesh Options

Comparison of Stainless Steel Wire Mesh Grades and Finishes

When choosing stainless steel wire mesh, understanding grades and finishes is essential. Stainless steel is graded based on its composition and resistance to corrosion. Common grades include 304 and 316. Grade 304, often found in kitchen equipment, offers decent corrosion resistance. However, it may not withstand saltwater environments. In contrast, grade 316 is ideal for marine applications. It has better resistance due to added molybdenum.

Tips: Consider your environment. If you are near saltwater, opt for grade 316. For indoor uses, grade 304 may suffice.

Finishes also play a crucial role. A polished finish can enhance aesthetics and reduce dirt accumulation. A coarse finish, however, provides better grip and stronger filtration. Choosing the right finish depends on your specific application. Some may prioritize looks, while others may need functional benefits.

Tips: Always evaluate the wire mesh's purpose. A fine finish might be great for decorative purposes. Yet, it may not perform well in heavy-duty situations. Don’t overlook the importance of finishing touches.

Top Brands and Products for Stainless Steel Wire Mesh in 2026

In 2026, the stainless steel wire mesh market continues to expand. Industry experts project a compound annual growth rate (CAGR) of 5% for this sector through 2027. This growth is fueled by diverse applications in construction, automotive, and filtration. Key parameters include wire diameter, mesh size, and tensile strength, impacting the product choice for varied needs.

Choosing the right stainless steel wire mesh can feel daunting. Consider the mesh type that suits your project best. For example, welded mesh provides higher strength, while woven mesh offers flexibility. Always verify the corrosion resistance of the material. Not all alloys perform the same way in different environments.

Tips: Always request a sample before purchasing. Observing the product in real-world conditions can reveal performance aspects you might miss online. Also, conduct a thorough comparison of suppliers. Quality can vary significantly, and lower pricing isn’t always an indicator of value. A small oversight now can lead to bigger issues down the line.

Maintenance Tips for Longevity of Stainless Steel Wire Mesh Products

Maintaining stainless steel wire mesh requires regular attention. Clean it periodically to avoid buildup. Use mild detergents and warm water for washing. A soft brush can help remove debris without scratching the surface. Rinsing thoroughly is crucial. Leftover soap can lead to corrosion over time.

Inspect the mesh for any signs of damage. Look for rust spots or loose wires that could compromise its integrity. Address issues immediately to prevent further deterioration. Regular checks should be part of your routine. For outdoor installations, consider reapplying protective coatings. This adds a layer of defense against the elements.

Avoid harsh chemicals during cleaning. They can weaken the metal and lead to quicker wear. Storing the mesh in a dry area extends its lifespan. Moisture is a common enemy. Even small teardrops of water can cause problems. By integrating these practices, you can ensure your stainless steel wire mesh serves you well over the years.