Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowUnderstanding the Benefits of Inkjet Coders in Modern Packaging Industries

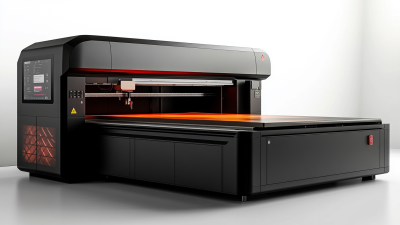

In the rapidly evolving landscape of modern packaging industries, Inkjet Coder technology plays a pivotal role in enhancing production efficiency and product quality. As companies strive to meet increasing consumer demands and regulatory compliance, the integration of Inkjet Coders into their packaging processes emerges as a strategic solution. These versatile devices not only facilitate high-speed printing of essential information such as expiration dates, batch numbers, and barcodes but also ensure that these markings are clear and durable.

This article will explore the numerous benefits of Inkjet Coders, including cost-effectiveness, adaptability to various materials, and the ability to maintain compliance with industry standards. By understanding how to effectively implement and utilize Inkjet Coders, packaging professionals can significantly improve their operational workflows and deliver products that meet both consumer expectations and regulatory requirements.

How to Choose the Right Inkjet Coder for Your Packaging Line

When selecting the right inkjet coder for your packaging line, it is essential to consider several key factors that can influence both efficiency and product quality. One of the primary considerations is the type of products being packaged.

Different inkjet coders are designed for various surfaces, such as porous or non-porous materials. Understanding the specific requirements of your packaging, including the required print resolution and speed, can guide you toward a suitable model.

Another crucial aspect is the operational environment of the packaging line. Factors such as temperature, humidity, and the presence of dust can impact the performance of inkjet coders. Additionally, ease of maintenance and support availability should be evaluated, as these can affect long-term operational efficiency. Ultimately, investing time in assessing these criteria will help ensure that the chosen inkjet coder meets your production needs while providing optimal reliability and functionality.

How to Optimize Production Efficiency with Inkjet Coders

Inkjet coders play a vital role in enhancing production efficiency within modern packaging industries. These versatile devices offer rapid and precise printing capabilities, significantly reducing downtime during packaging operations. According to a report by Smithers Pira, the demand for digital printing in packaging is projected to grow at a CAGR of 7.9% through 2025, driven largely by advancements in inkjet technology. By integrating inkjet coders into production lines, companies can achieve quick changeovers and minimize waste, contributing to both cost savings and improved sustainability.

To optimize the use of inkjet coders, businesses should focus on a few key strategies. First, maintaining the coders regularly ensures consistent performance and high-quality output. Secondly, selecting the right ink formulation for specific substrates can enhance print durability and compliance with industry standards. A study published by AIPIA highlighted that 30% of companies reported increased production agility after adopting high-quality inkjet systems. Finally, investing in training for operators can significantly improve the efficiency with which these systems are utilized, ultimately leading to enhanced overall productivity.

**Tips:**

1. Regular maintenance checks can uncover potential issues before they cause production delays.

2. Experiment with different ink types and substrates to find the optimal combination for your specific needs.

3. Provide comprehensive training for employees to familiarize them with advanced features and troubleshooting techniques of inkjet coders.

How to Ensure Quality Control Using Inkjet Coders

Inkjet coders have revolutionized quality control in modern packaging industries by providing a reliable and efficient method for marking and coding products. With the ability to print variable data such as expiration dates, barcodes, and batch numbers directly onto packaging, inkjet coders enhance traceability and compliance with industry regulations. For manufacturers, this means improved accuracy in inventory management and reduced risk of costly recalls due to labeling errors.

To ensure quality control when using inkjet coders, regular maintenance and calibration are essential. Adjusting ink viscosity and head alignment can significantly influence print quality. It’s also crucial to monitor the print resolution to maintain clarity, especially for barcodes that require precise scanning.

**Tips:**

- Schedule routine maintenance checks to keep the inkjet coders functioning optimally.

- Implement a consistent training program for operators to familiarize them with troubleshooting common issues.

- Conduct periodic audits of printed codes to evaluate their legibility and adherence to quality standards.

Understanding the Benefits of Inkjet Coders in Modern Packaging Industries - How to Ensure Quality Control Using Inkjet Coders

| Feature | Description | Benefits |

|---|---|---|

| High-Speed Printing | Inkjet coders can print at speeds exceeding 300 meters per minute. | Increases production efficiency and reduces bottlenecks. |

| Versatile Media Compatibility | Works on various surfaces like plastic, glass, and metal. | Widens packaging options and enhances branding opportunities. |

| High-Resolution Printing | Prints clear, sharp codes and graphics at high resolutions. | Improves product traceability and enhances customer appeal. |

| Ease of Integration | Can be easily integrated into existing packaging lines. | Minimizes downtime and installation costs. |

| Low Maintenance Costs | Requires less frequent maintenance compared to other technologies. | Reduces overall operation costs. |

| Environmental Friendly Inks | Utilizes inks that are less harmful to the environment. | Aligns with sustainability goals and regulations. |

How to Integrate Inkjet Coders into Existing Packaging Systems

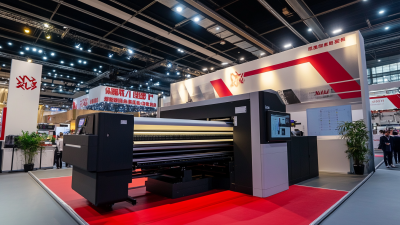

Integrating inkjet coders into existing packaging systems can significantly enhance operational efficiency and product traceability in modern packaging industries. According to a recent report by Smithers Pira, the global market for coding and marking technologies is expected to grow by 4.5% annually, reaching approximately $4.3 billion by 2026. Inkjet coding systems stand out due to their ability to generate high-quality, variable text and images at high speeds, making them ideal for fast-paced production environments.

To successfully integrate inkjet coders, companies should first assess their current packaging lines to identify compatibility. This involves evaluating existing machinery and workflow processes. Key considerations include the type of ink used—solvent-based or water-based—and the surfaces being printed on, as these factors affect adhesion and drying times. Furthermore, investing in training for operational staff is crucial, as proper usage ensures reduced downtime and maximizes output. Industry data indicates that an effective integration can reduce coding errors by up to 80%, which directly impacts overall production quality and compliance with regulations. By prioritizing these strategies, businesses can leverage the full benefits of inkjet coding technology while maintaining their competitive edge in the packaging sector.

How to Maintain and Troubleshoot Inkjet Coders Effectively

Inkjet coders play a crucial role in modern packaging industries, ensuring that products are accurately labeled and tracked throughout the supply chain. One key aspect of maintaining these coding systems is effective troubleshooting. With recent advancements, many inkjet printers now feature self-troubleshooting capabilities, which significantly reduce coding downtime and costs. This innovation allows machines to automatically perform diagnostics, eliminating the need for constant oversight from skilled operators or service technicians.

To maximize the benefits of inkjet coders, consider these tips for maintenance and troubleshooting: regularly check and clean print heads to prevent clogs, which can lead to print quality issues. Additionally, keep an eye on ink levels and replace cartridges as needed to avoid interruptions in production. When a problem arises, refer to the printer's diagnostic tools first, as they can point you to the root cause without extensive manual intervention.

Incorporating these practices not only enhances productivity but also ensures consistent high-quality outputs. As inkjet technology continues to evolve, staying informed about these advancements will allow businesses to maintain their competitive edge while minimizing operational disruptions.

Understanding the Benefits of Inkjet Coders in Modern Packaging Industries

This bar chart illustrates the percentage benefits of inkjet coders in the modern packaging industry, highlighting factors such as cost efficiency, flexibility, speed, print quality, and maintenance. Understanding these benefits can guide businesses in optimizing their packaging operations.

Related Posts

-

Ultimate Guide to Choosing the Best Inkjet Coder: Key Features and Industry Insights

-

5 Best Industrial Printer Machines for Efficient Production in 2023

-

Unlocking Global Opportunities at the 137th Canton Fair with Industrial Inkjet Printing Innovations

-

Ultimate Guide to Choosing the Best Cij Printer for Global Procurement Success

-

Innovative Examples of Inkjet Coder Applications Driving Efficiency in Modern Manufacturing

-

Understanding the Differences Between Continuous Inkjet Printers and Other Coding Technologies